A researcher at University of Limerick has developed a low-cost, environmentally friendly sensor that can detect damage in pipelines and could save water as a result.

The damage detection sensor uses highly sensitive, eco-friendly crystals that generate an electrical signal in response to a leak.

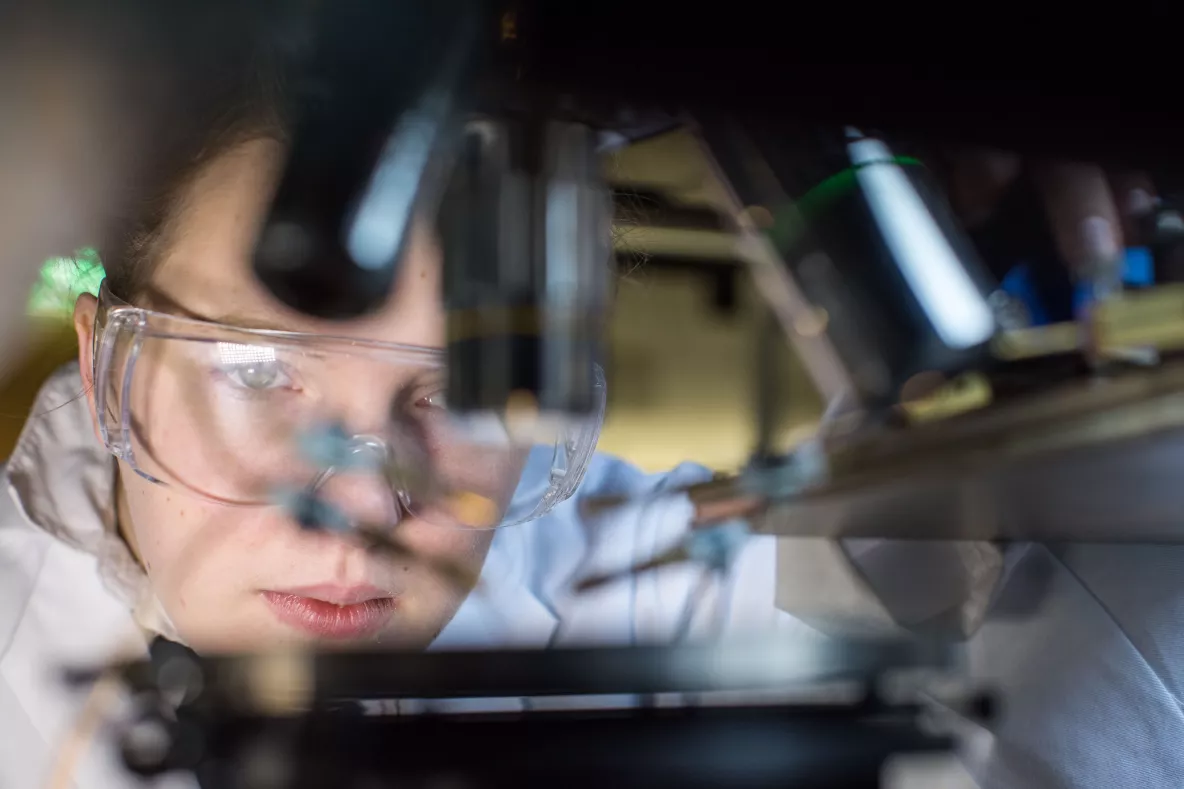

It is the first validation of these biological crystals for real world applications, according to Dr Sarah Guerin, a postdoctoral researcher at the Department of Physics and the Bernal Institute in UL, who has been developing amino acid crystal devices since 2017.

An Irish research collaboration between the Bernal Institute at UL and the Dynamical Systems and Risk Laboratory in University College Dublin has validated the crystal-based sensor.

The journal Cell Reports Physical Science has just published a study on the findings of the innovative research.

“The sensor is made of crystallised amino acids that are sensitive enough to detect leaks as small as 2mm,” said Dr Guerin.

“Computer simulations show that they generate electricity in response to a force - such as strain or vibration - known as the piezoelectric effect.

“Biomolecular piezoelectric materials such as these offer an inexpensive, non-toxic and renewable alternative to current commercial piezoelectric devices, which rely on toxic heavy elements or require heavy processing,” she explained.

Leak detection in fluid-carrying pipes is crucial for sustainable water access, and vibration-based techniques have proven to be effective at early detection of leak onset. Current commercial solutions are either battery powered, or if piezoelectric, very costly.

In addition, most commercial accelerometers have rigid structures, making them unsuitable for bonding to curved pipes, explained the UL researcher.

“This sensor has a number of advantages over current technologies,” said Dr Guerin.

“It is flexible, cheap to make, and outperforms ceramics and polymers that are used in these structural health monitoring applications. The fabrication process is suitable for mass production of these devices,” she added.

Professor Vikram Pakrashi of UCD, a senior author on the study who has developed extensive testing facilities for validating materials for structural health monitoring that simulate infrastructural damage in for example buildings and pipelines, said the findings of the research were significant.

“These amino-acid-based sensors will provide real-time sensing of pipe degradation, allowing for data-driven decision making on repair and maintenance, aiding in the global challenge of equitable water access,” he explained.

“This is the first time such materials have been applied for real engineering problems and it has addressed one of the core challenges of our time – water,” added Dr Favour Okosun of UCD, whose doctoral research created the application of this sensor.