What are MPMs?

In order to understand the significance of MPMs it is necessary to first understand the three stages of drug discovery and development, D3. Stage 1 of D3 starts with the discovery of a specific molecule, a lead compound, which is an outcome of the medicinal chemistry process. Medicinal chemistry involves the synthesis of a family of derivatives of a parent molecule to optimize physicochemical and biological properties in order to discover the lead compound. Once a molecule with promising biological activity has been identified then a second stage, which is called pre-formulation, identifies a solid form of the molecule (i.e. a material) that has optimal physicochemical properties. This material is called a drug substance or active pharmaceutical ingredient (API). When an API is combined with other materials, called excipients, it enters the third and final stage of D3, also known as formulation. An excipient is a pharmacologically inactive ingredient that enables a drug product (e.g. it controls the rate of disintegration and dissolution or helps to prevent moisture from entering the drug product, etc.).The drug product or medicine that is thereby produced is most commonly produced in the form of a tablet.

MPMs can be defined as multiple component crystalline materials in which at least one component is a drug substance or API and they have the potential to profoundly impact the second stage of D3. When the second component(s) of an MPM is a solvent molecule or a water molecule, solvates and hydrates are formed, respectively. When the second component(s) is another solid compound (the coformer) it is called a pharmaceutical cocrystal. When both the API and coformer(s) are uncharged, the resulting material is called a molecular pharmaceutical cocrystal2 whereas if one or more of the components are charged then the term ionic pharmaceutical cocrystal can be applied.3

Why are MPMs of interest?

When APIs form MPMs the driving force is typically a supramolecular synthon (e.g. a hydrogen bond), which exploits the supramolecular chemistry and shape of the API, the very features that enable the biological activity of an API, to control solid-state composition and form of an API. To put this in context, in pharmaceutical science, the study of the crystal form of an API, in particular, its physicochemical properties relevant to clinical performance and long term stability, represents an important aspect of modern drug development. Indeed, even long-used drugs such as aspirin and many antibiotics owe their purity and storage-stability to their existence as crystalline solids. Pharmaceutical cocrystals only emerged in the early part of the past decade as a promising new weapon in the arsenal of drug development, fuelled by the realization that they can be rationally designed and profoundly impact the physicochemical properties and, therefore, bioavailability of APIs.4 Cocrystals are unlike traditional classes of crystal form such as polymorphs, salts and solvates for the following reasons:

- They can be designed by judicious selection of complementary coformers;

- They can exhibit more efficient packing than the individual coformers;

- They are far more diverse in terms of composition than traditional pharmaceutical materials. They can, therefore, enable an API to have the requisite physicochemical properties (e.g. solubility and stability) to function as a drug product (medicine).

Consequently, MPMs offer significant opportunities for intellectual property and improved medicines. It should, therefore, be unsurprising that there has been a concurrent rise in patent activity concerning pharmaceutical cocrystals5 and regulatory bodies are developing guidelines that address approval of pharmaceutical cocrystals in drug products.6

Specific MPM Platforms of current interest to UL researchers

What are Ionic Cocrystals?

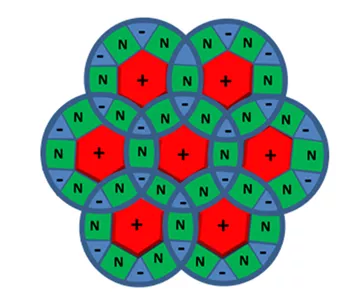

The development of novel solid forms of pharmaceutical compounds, drug substances, is an important aspect of modern pharmaceutical science because the physicochemical properties of the solid form (i.e. the material) of a pharmaceutical compound (i.e. the molecule) are what enable it to ultimately become part of an effective drug product (i.e. the medicine). Ionic cocrystals (ICCs)1 have recently emerged as a class of multi-component pharmaceutical materials (MPMs) of scientific and practical interest. ICCs can be defined as “Multi-component materials formed from a salt and a molecular or ionic compound.” The general formula of ICCs is A+B-N where A+ is a cation, B- is an anion and N is neutral molecule or another salt. If at least one of the components of the ICC is a pharmaceutical compound then there is considerable opportunity to modulate the physicochemical and biological efficacy of the pharmaceutical compound.

How are Ionic Cocrystals prepared?

Ionic cocrystals can be conveniently prepared from a salt + another neutral molecule or salt via solution crystallization, slurry or mechanochemistry (grinding).

Why are Ionic Cocrystals of interest?

- Although the first ICC was reported at least as far back as 1843 (Kobell, sodium chloride with glucose)2 they remain an underexplored class of compounds that have barely been studied in the context of pharmaceutical science.1,3 They therefore offer an opportunity for new fundamental science concerning the subject of crystal engineering, for improving the physicochemical properties of pharmaceutical compounds and for development of intellectual property.4

- Single component solid forms offer very limited opportunities with respect to diversity of physicochemical properties whereas 2-component solid forms (e.g. molecular cocrystals) might lead to dozens of new drug substances that enhance bioavailability5 and thereby find utility in a drug product. ICCs offer even greater diversity than 2-component solid forms since they are based upon 3-component solid forms for which two components can be varied without changing the chemical structure of the pharmaceutical compound. In principle, this provides exponentially more solid forms than even for 2-component solid forms.