Overview:

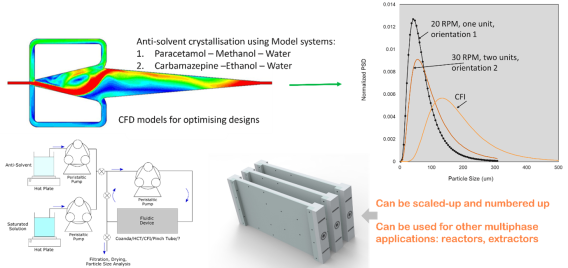

The project aims to develop a systematic methodology for the design, optimization and scale-up of continuous crystallizers without moving parts for realizing better control of particle size distribution and other critical quality attributes.

Crystallization is a critical purification process in the pharmaceutical industry and is commonly performed in batch mode. It has been well established that continuous processes have an edge over batch processes in terms of yield, consistency of products and control of the process conditions. The industry is gradually making the transition to continuous operation, but some issues prove to be a hindrance to this transition. We aim to identify these obstacles and develop an ideal crystallizer which will give the user absolute control over the Critical Quality Attributes of the product crystals such as particle size distribution, yield and polymorphs.

Certain issues faced in the continuous operation of crystallization can be traced back to the presence of agitators which are instrumental in maintaining uniform conditions inside the crystals. We work on developing passive fluidic devices or fluidic devices without moving parts such as the fluidic oscillator, coiled flow inverter (CFI) and oscillatory baffled reactors among others to perform as crystallizers. Computational Fluid Dynamics and Population Balance Modelling are employed to simulate the flow conditions and kinetics in the crystallizers. The results obtained via the computational methods are validated using experimental results.

On the experimental front, we also study the application of Process Analytic tools for online monitoring of the process to make the continuous mode of operation more robust. Some of these PAT tools include the Focused Beam Reflectance Measurement probe – used to monitor the Chord Length Distribution (CLD) which can be translated to the Particle Size Distribution (PSD) using the CLD-PSD tool developed in-house, the Fourier Transform-Infra-Red (FT-IR) spectroscopy probe – used to monitor the concentration of solute in the solvent at any given point of time and the Raman probe – helps track changes in the polymorphic form of the crystals.